When a hospital loses power, seconds matter. When a data center goes dark, millions of dollars are at risk. And when a factory shuts down, production delays can ripple through entire supply chains. In these moments, relying on a single backup generator is like putting all your trust in one safety net—if it fails, everything stops.

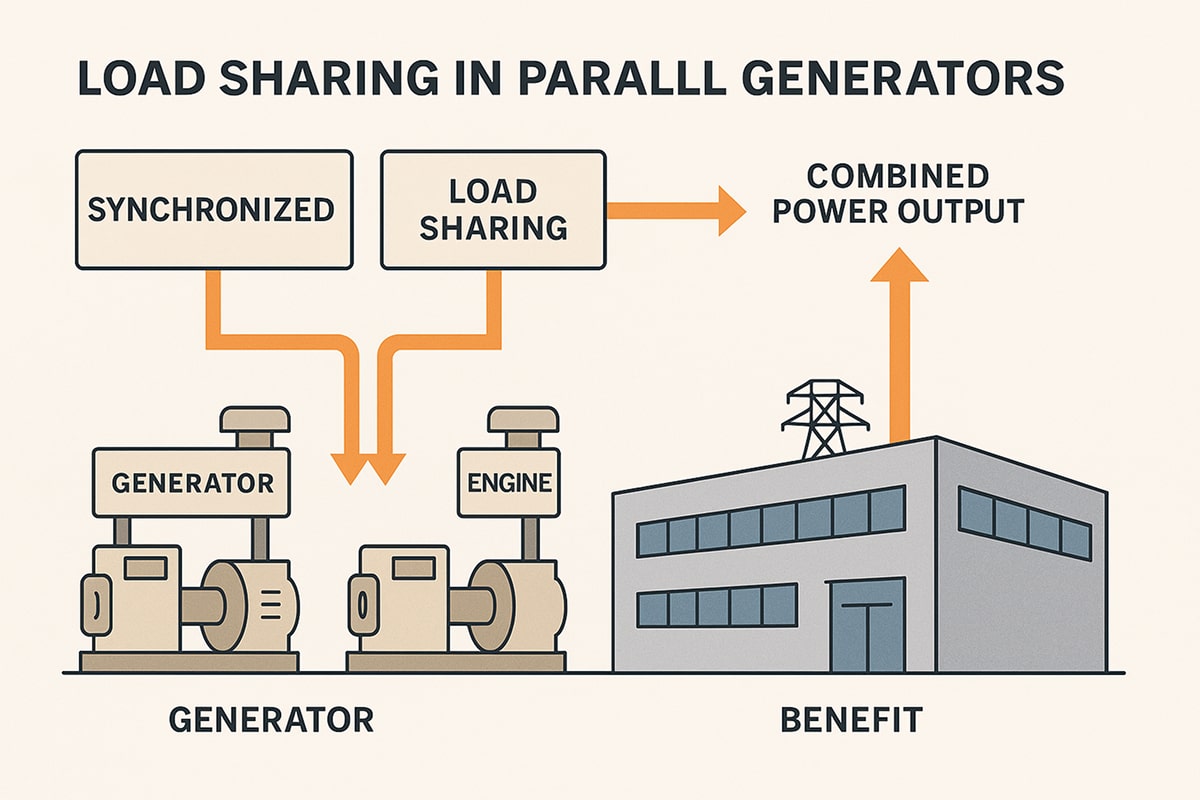

That’s why parallel generators have become the standard for facilities that demand reliability, scalability, and continuous backup power. Instead of depending on one oversized generator, businesses are choosing systems of multiple generators working together through load sharing and generator synchronization.

This guide explains what parallel generator operation is, how it works, and why it matters for large facilities like hospitals, data centers, and industrial plants.

What Are Parallel Generators?

In simple terms, parallel generator operation means running two or more generators at the same time so they function as one system. Instead of having one generator provide all the power, the electrical demand is divided across multiple units.

Think of it like a team of rowers in a boat. One person can move the boat, but if everyone rows in sync, the boat moves faster and more steadily. Parallel generators operate the same way—working together, in sync, to produce the power your facility needs.

What is Generator Synchronization?

For generators to run in parallel, they must stay synchronized. That means:

- Voltage: Both generators must produce the same voltage level.

- Frequency: Both must operate at the same cycles per second (measured in hertz).

- Phase angle: Their electrical waveforms must align so they don’t clash.

If synchronization isn’t maintained, the generators can work against each other instead of together. Imagine two people trying to push a heavy cart, but one pushes forward while the other pulls backward. Not only would the cart not move properly, but the effort could damage both people.

In generators, improper synchronization can cause severe electrical damage, overloads, and even system failure. That’s why automatic synchronization controls are critical for industrial systems.

Understanding Load Sharing

Once synchronized, generators must also divide the electrical demand evenly. This process is called load sharing.

Load sharing ensures:

- No single generator is overloaded.

- All units run efficiently, avoiding wasted fuel.

- The system adapts to fluctuating demand by balancing power output.

For example, in a hospital, the power demand spikes when imaging equipment runs. With load sharing, two or more generators automatically adjust their output so that one unit isn’t carrying the entire burden.

Benefits of Parallel Generator Operations

Running parallel generators offers advantages that a single generator can’t match:

1. Redundancy and Reliability

If one generator fails, the others continue running. Your facility avoids total shutdown and keeps essential systems powered.

2. Scalable Power

Need more capacity? Add another generator to the system. You don’t need to replace your entire setup with a bigger unit.

3. Greater Efficiency

Generators run best at about 70–80% load. With multiple units, you can turn generators on and off as demand changes, keeping them in the efficiency sweet spot.

4. Cost Control

Multiple smaller units can be more cost-effective than one oversized generator. They’re easier to maintain and provide flexibility for growth.

5. Maintenance Flexibility

One generator can be taken offline for service while the others continue powering your facility. This keeps operations running without interruption.

Where Are Parallel Generator Systems Used?

Parallel generator systems are not just for massive utility providers. Many industries depend on them daily:

- Hospitals: Life-support systems and surgical equipment cannot fail. Redundancy ensures power is always available.

- Data Centers: Servers and cooling systems must run nonstop. Downtime costs are often higher than the price of the generator system itself.

- Large Industrial Plants: Production lines, heavy machinery, and climate systems need consistent power to avoid costly interruptions.

- Marine & Offshore Operations: Ships, rigs, and offshore facilities rely on multiple units for safety and operational flexibility.

Safety and Best Practices in Parallel Operations

While the benefits are clear, parallel generator operation requires proper setup and safety protocols:

- Certified Synchronization Gear: Never attempt to connect generators without approved paralleling equipment.

- Grounding: All generators in the system must be grounded correctly to avoid electrical hazards.

- Load Monitoring: Automatic load-sharing controls prevent overloading and extend equipment life.

- Professional Installation: Parallel systems should always be designed and installed by experienced technicians.

Trying to “DIY” generator paralleling is dangerous. Incorrect synchronization can lead to catastrophic failures.

Choosing the Right Parallel Generator Setup

When planning a parallel generator system, decision-makers should consider:

- Fuel Source: Diesel and natural gas are the most common for industrial applications. Each has benefits in cost, storage, and availability.

- Load Profile: Understanding whether your facility has steady or fluctuating power needs will guide system design.

- Control Systems: Modern paralleling controls automate synchronization and load sharing, making operations seamless.

- Compliance: Local codes, safety standards, and emissions requirements must be factored into design.

At React Power Solutions, we’ve helped facilities worldwide configure parallel generator systems that meet both current and future needs.

Cost Comparison: Parallel Generators vs. One Large Generator

For many businesses, the first question is cost. Should you invest in one large generator or multiple units in parallel? The answer depends on your priorities, but in many cases, paralleling is the smarter choice.

- Upfront Cost: One high-capacity generator often carries a bigger price tag than two or three smaller generators with equivalent combined output. Spreading investment across smaller units can reduce capital costs.

- Operating Efficiency: Large generators frequently run at partial loads, which is inefficient. Parallel systems can shut down unneeded units, keeping the others in their optimal load range for better fuel economy.

- Maintenance: Service costs for one massive machine can be high, and downtime halts operations. With parallel generators, maintenance can be rotated across units without full system shutdown.

- Scalability: Expanding a facility doesn’t require replacing your generator entirely. You can add new units to the parallel system, which reduces long-term costs.

When comparing lifetime expenses, businesses often find that parallel generator systems provide better value because they balance reliability, efficiency, and long-term flexibility.

Parallel Generators in Action

To see the benefits in practice, consider a regional hospital. React Power Solutions designed a system of three generators operating in parallel with N+1 redundancy. This means two units carry the hospital’s normal load, and a third stands ready as a backup. When one generator undergoes maintenance, the others seamlessly keep life-support systems, surgical suites, and diagnostic equipment powered without interruption.

Another example comes from a Gulf Coast data center. As customer demand grew, the facility needed additional power capacity. Instead of replacing its existing setup, the center simply added another generator into the parallel system. The expansion was quick, cost-effective, and provided enough flexibility for future growth.

The Future of Parallel Generators

Parallel systems are evolving with smarter controls and integration into hybrid power grids. Businesses are increasingly combining:

- Diesel and natural gas units for fuel flexibility.

- Renewables like solar or wind with generator backups for cleaner energy.

- Advanced digital controls that monitor and optimize generator performance in real time.

This shift makes generator systems not only more reliable but also more adaptable for the long term.

Why Work with React Power Solutions?

Established in 2016, React Power Solutions has become a trusted provider of commercial and industrial generator systems worldwide. With over 40 years of combined experience, our team delivers:

- Diesel and natural gas engines.

- Portable and standby generators.

- Custom paralleling controls for complex facilities.

- Marine and offshore applications.

- Procurement and logistics expertise for global delivery.

From the initial inspection to final installation, we ensure every generator system is built for reliability, efficiency, and long-term value.

Power Without Compromise

For facilities where downtime is not an option, parallel generators offer the best combination of redundancy, scalability, and efficiency. By running multiple units in synchronization, businesses gain peace of mind knowing they’ll always have reliable backup power.

Whether you’re managing a hospital, a data center, or a large industrial operation, React Power Solutions can help design and deliver the right generator system for your needs.

Contact us today to discuss how parallel generator operations can protect your business.